Within the present rapid-paced enterprise setting, effectivity is the secret, particularly in manufacturing. With the rise of automation, factories are remodeling like by no means earlier than. From robotic meeting traces to sensible stock administration methods, automation is revolutionizing how merchandise are made and distributed.

This text will delve into the position of automation in trendy manufacturing, exploring its influence on productiveness and competitiveness. It is going to additionally check out how the modern contributions of Locus Robotics are revolutionizing warehouse operations and additional enhancing effectivity within the manufacturing panorama.

1. Streamlining Manufacturing

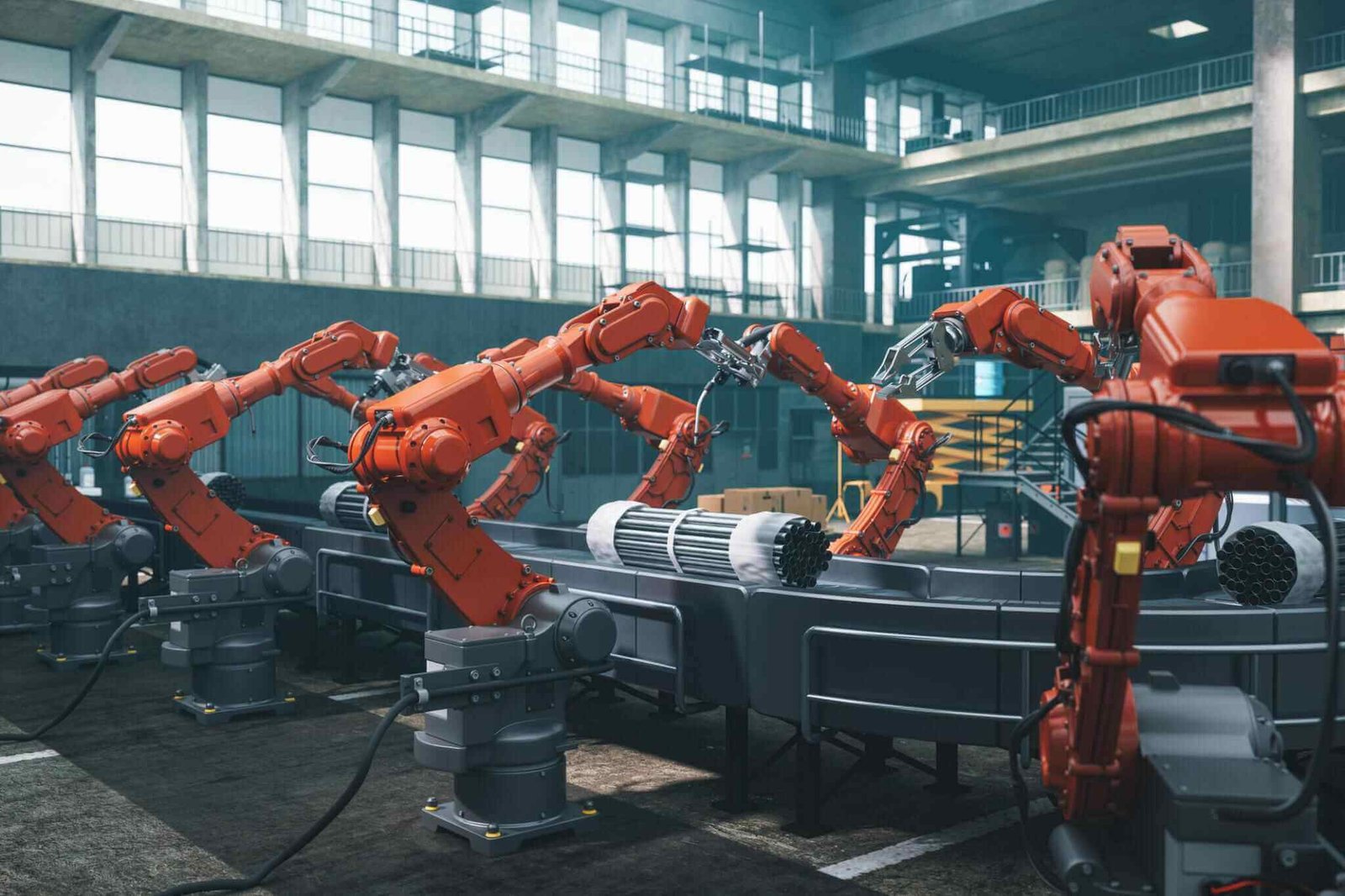

Gone are the times when manufacturing relied solely on handbook labor. Robotic meeting traces have taken middle stage, providing unmatched precision and velocity. These robots are programmed to carry out repetitive duties with utmost accuracy, resulting in larger manufacturing charges and decrease error margins. By automating the meeting course of, producers can considerably cut back cycle instances and ramp up manufacturing to satisfy rising calls for.

2. Optimizing Provide Chains

Stock administration is a vital side of producing, and automation has caused important enhancements on this space. Using warehouse options powered by superior applied sciences, resembling RFID tagging and barcode scanning, firms can now observe stock in real-time with pinpoint accuracy. This degree of visibility allows higher forecasting, environment friendly inventory replenishment, and minimization of stockouts, in the end resulting in price financial savings and improved buyer satisfaction.

3. Affect on Productiveness and Competitiveness

The combination of automation into manufacturing processes has a profound influence on general productiveness and competitiveness. By automating routine duties, employees can focus their abilities and experience on extra value-added actions, resembling problem-solving and innovation. This not solely enhances worker satisfaction but in addition drives steady enchancment throughout the group.

Furthermore, automation permits producers to function 24/7 with out the constraints of human fatigue, resulting in elevated output and shorter lead instances. This agility allows firms to reply swiftly to altering market dynamics and buyer calls for, staying forward of the competitors in a quickly evolving panorama.

4. High quality Management and Inspection

Automation isn’t nearly velocity and effectivity; it additionally performs an important position in sustaining product high quality. Automated inspection methods geared up with superior sensors and machine imaginative and prescient know-how can detect defects with unparalleled accuracy, making certain that solely high-quality merchandise attain the market. Producers can cut back waste and enhance buyer satisfaction by minimizing defects and rework.

5. Versatile Manufacturing Programs

Conventional manufacturing setups usually wrestle to adapt to altering manufacturing necessities. Nevertheless, with versatile manufacturing methods enabled by automation, firms can simply reconfigure manufacturing traces to accommodate various product specs and demand fluctuations. This agility permits producers to reply rapidly to market modifications and optimize useful resource utilization.

6. Worker Upskilling and Coaching

The introduction of automation could increase considerations about job displacement. Nevertheless, it additionally presents alternatives for worker upskilling and coaching. By investing in coaching packages targeted on robotics, programming, and knowledge evaluation, firms can empower their workforce to function and keep automated methods successfully. This not solely enhances worker engagement but in addition ensures a easy transition to the automated manufacturing setting.

7. Environmental Sustainability

Automation can contribute to environmental sustainability by optimizing useful resource utilization and lowering waste. Automated manufacturing amenities can considerably decrease their carbon footprint by streamlining manufacturing processes and minimizing power consumption. Moreover, automation allows predictive upkeep, lowering the probability of apparatus failures and the related environmental influence.

8. Locus Robotics – Revolutionizing Warehouse Operations

One noteworthy instance of automation in motion is Locus Robotics. Their modern autonomous cell robots (AMRs) are designed to work collaboratively with human employees in warehouse environments, enhancing effectivity and order achievement velocity. These robots navigate by the warehouse autonomously, choosing up and transporting objects to designated areas with precision and velocity. By automating tedious and labor-intensive duties, they assist firms streamline their warehouse operations, cut back operational prices, and enhance general productiveness.

Conclusion

In conclusion, automation is reshaping the manufacturing panorama in profound methods. From robotic meeting traces to sensible stock administration options, automation has grow to be the driving power behind elevated effectivity and competitiveness within the trade. As know-how continues to advance, the potential for additional optimization and innovation in manufacturing processes is limitless.

Embracing automation is not only about maintaining with the instances—it’s about staying forward of the curve and unlocking new ranges of effectivity and productiveness.